DISCOVER THE EASIEST WAY TO SCHEDULE & MANAGE PRODUCTION

Run your operations on reality.

See how Amper's production management software helps you track, plan, execute, and improve operations.

No complex setup or confusing interface.

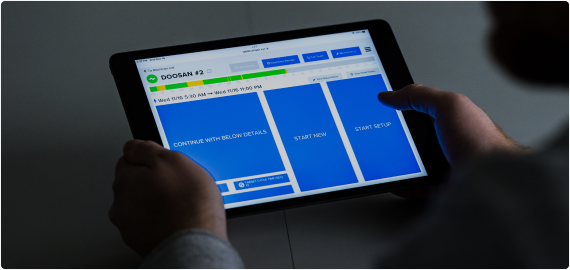

![]() Schedule and adjust jobs in real time

Schedule and adjust jobs in real time

![]()

Simulate production with AI-driven forecasts

![]() Integrate seamlessly with your ERP

Integrate seamlessly with your ERP

Not ready to learn how Amper suits your specific goals? Watch a product overview first.

1. Fill out the form 2. Choose a time

3. See Amper in action!

Top manufacturers trust Amper

WHAT WE DO

AMPER HAS REIMAGINED HOW YOU SCHEDULE PRODUCTION

Traditional production scheduling solutions are hard to set up and harder to use. Amper uses real-time AI-powered production data to make scheduling a breeze.

FEATURED SOLUTIONS

A CENTRAL HUB TO SCHEDULE & RUN YOUR OPERATIONS

Level up your ERP by connecting the front office with the reality of the shop floor. Replace your outdated spreadsheets with modern tools to achieve your production goals.

MEET ON-TIME DELIVERY

SHIP PARTS ON TIME—EVERY TIME

Schedule, simulate, and adjust jobs with ease. You’ll always know when a job is projected to end thanks to live updates and predictive forecasts.

Any adjustments get automatically pushed out, so teams are always aligned and production stays on track.

INCREASE PRODUCTIVITY

TAP INTO HIDDEN CAPACITY & IMPROVE OEE

Take a magnifying glass to your utilization, late starts/early stops, downtime drivers, and other inefficiencies.

Detailed reports and automated alerts help you identify patterns and make adjustments to tap into the extra capacity hiding around your plant.

REDUCE DIRECT COSTS

BOOST THROUGHPUT WITHOUT EXTRA RESOURCES

Eliminate inefficiencies and improve labor efficiency so you can increase throughput without investing extra resources.

Plus, see how much your production issues are costing you and improve what’s actually holding you back.

AN MES FUELED BY REAL-TIME IOT DATA

We've designed a suite of tools that makes it quick and simple. Automatically pull live data from every machine, team, and system.

-

ELECTRICAL SIGNALS

Connects non-invasively to any machine in minutes to read electrical signals. -

DIGITAL SIGNALS

Reads 0-24V digital control signals to track cycles and industrial sensors.

Reads 0-24V digital control signals to track cycles and industrial sensors. -

PLC INTEGRATION

Connects to PLC controls seamlessly for a unified view of your data.

Connects to PLC controls seamlessly for a unified view of your data. -

LINKED ASSETS

Digitizes data from hardware-free assets (e.g. rarely used machines).

Digitizes data from hardware-free assets (e.g. rarely used machines).

HOW WE PULL DATA

COVER 100% OF YOUR PLANT WITH QUICK-DEPLOY IOT SENSORS

“We had Amper up and running on all of our machines after one day—with no need to stop production.”

WHY AMPER?

IT'S FASTER AND EASIER–STRAIGHT OUT OF THE BOX

CONNECT TO ANY MACHINE

Our self-install devices are easy to connect to machines, regardless of age or type.

.png?width=521&height=267&name=Frame%2049%20(1).png)

GET REAL-TIME & PREDICTIVE INSIGHTS

Simulate and forecast production or ask the in-app CI agent for project plans tailored to your goals.

EMPOWER OPERATORS

Copilot, Amper’s operator interface, lets them track job progress and call for support with ease.