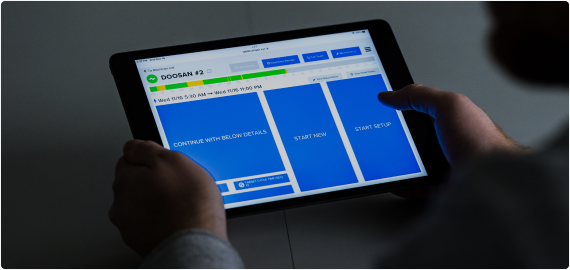

Know exactly what’s slowing you down. And fix it with Amper's OEE monitoring software.

![]() Track OEE in real time.

Track OEE in real time.![]() Identify bottlenecks.

Identify bottlenecks.![]() Eliminate past due backlogs.

Eliminate past due backlogs.

Not ready to chat? Watch a short product overview first.

.png?width=764&height=400&name=ABX%20ads%20-%20template%20(2).png)

"We started the trial on a bottleneck resource that had roughly 35% OEE. By the time we finished up the trial, we were closer to 80-85% OEE–just by understanding better where our downtime was, and why we had it."

Mark Ritchie

Operations Manager, Gleason

OEE software built for real manufacturers. Proven in the real world.

Uncover the truth behind your plant’s performance.

Spot bottlenecks fast

Real-time visibility makes it clear what’s causing slowdowns.

Get more from what you have

Improve throughput and eliminate waste—without adding headcount.

Make better calls, faster

Data-backed decisions mean fewer surprises and stronger results.

Simple to use.

Built to deliver.

-

Tracks any machine or manual process

Connect any machine—regardless of age, brand, or type—with zero code and minimal disruption. Even manual workstations like assembly or inspection are tracked with simple digital tools. If it runs in your plant, Amper can track it.

-

Real-time dashboards for instant visibility

See exactly what’s happening on the floor as it happens. Live dashboards show job status, machine performance, and operator activity—so teams can react fast, stay accountable, and hit their goals.

-

Labor and job tracking included

Track job progress and operator performance in one place. Compare actual vs. expected cycle times, spot coaching opportunities, and keep your entire team aligned and productive.

-

Automated reports and alerts

Stop chasing down data. Amper delivers scheduled reports and live alerts that highlight downtime, missed targets, and more—so you’re always a step ahead.

-

Actionable insights for real CI

Amper doesn’t just surface problems. It shows you where to focus and why, using AI-powered tools to suggest improvement projects and quantify potential impact. It’s the continuous improvement engine your plant’s been missing.

WHAT WE DO

See Amper's OEE Software in action.

Watch how Amper makes data-driven operations easy.